Colour separation unites circularity and aesthetics in plastic packaging

27 October 2025

In the run-up to the new European Packaging and Packaging Waste Regulation (PPWR), waste-to-product company Renewi and packaging manufacturer Teamplast are joining forces to overcome a key barrier to a more circular packaging chain: making white-coloured packaging from 100% recycled plastic available.

From virgin to fully recycled: a complex transition

Many companies are eager to become more sustainable, but the shift from virgin to recycled material often proves difficult in practice. “Our clients are committed to using 100% post-consumer recycled (PCR) material. PCR comes from the consumer or commercial waste stream - for example, a discarded package. However, due to a shortage of white recycled material, there was a real risk of reverting to virgin plastics. That was unacceptable,” says Robin Koning, Partner at Teamplast.

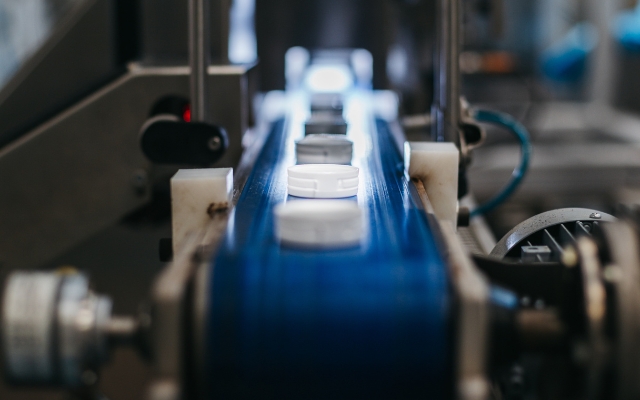

Renewi responded by investing in a colour-sorting installation in Eindhoven which separates white and neutral plastic flakes from other colours. This enables the production of high-quality PCR suitable for applications where both colour and quality are essential.

White packaging made from recycled plastic

Producing white packaging from recycled material is both a technical and aesthetic challenge. Recycled plastics typically contain mixed colours, resulting in a grey or brown base material. This has made it difficult to create white packaging without adding new virgin raw materials.

Thanks to Renewi’s advanced colour separation process, a pure, white-coloured plastic stream can now be produced; ideal for brands in sectors where colour and appearance are crucial, such as cosmetics and personal care.

Where the market previously often had to choose between circularity and aesthetics, Renewi and Teamplast make it possible to combine both. Brands can use fully recycled packaging without compromising on appearance or performance.

Anticipating European legislation

The collaboration comes at a strategic time. The upcoming European PPWR regulation sets stricter requirements for the use of recycled materials. Renewi and Teamplast are staying ahead of this by offering brands a future-proof solution.

“Virgin material is finite,” says Koning. “By using PCR, we give waste a new life and reduce our dependence on new raw materials. The transition requires courage, collaboration and a little pressure from regulation and customers.”

Jan-Pedro Vis, Director of Materials at Renewi, adds: “Our job is to make used plastics suitable again for high-quality applications. Thanks to colour separation, we can now also supply white PCR, a crucial step in making recycled material more attractive and widely usable. It proves that a more circular economy is achievable when you dare to invest in technology and work together across the value chain.”